What is an "spark"?

"Without sparks", "reduced spark", "spark resistant" or "spark-proof" are names given to metal instruments such as brass, bronze, Monel metal (copper-nickel alloy), aluminum-copper alloys (bronze aluminum) or copper-beryllium alloys (beryllium bronze).

Hand tools in common use are often made with steel alloys. The alloys used to produce non-sparking tools have a tensile strength lower than in steels normally used to make tools. Tensile strength less means that the metal has less strength or resistance compared to the tools tradizionalei. This also means that these tools are softer, wear out more quickly than normal steel tools, and must be replaced more frequently.

"Without sparks", "reduced spark", "spark resistant" or "spark-proof" are names given to metal instruments such as brass, bronze, Monel metal (copper-nickel alloy), aluminum-copper alloys (bronze aluminum) or copper-beryllium alloys (beryllium bronze).

Hand tools in common use are often made with steel alloys. The alloys used to produce non-sparking tools have a tensile strength lower than in steels normally used to make tools. Tensile strength less means that the metal has less strength or resistance compared to the tools tradizionalei. This also means that these tools are softer, wear out more quickly than normal steel tools, and must be replaced more frequently.

What is the most important thing to know about non-sparking tools?

This category of tools do not produce or generate sparks is sometimes referred to as "cold spark". These sparks cold have a low level of heat and are not able to turn on the carbon disulfide, which have the lowest point of ignition of any other substance known to man.

Non-metals such as wood, leather, and plastic are suitable for some tools such as shovels, scoops and scrapers or are not dangerous spark friction.

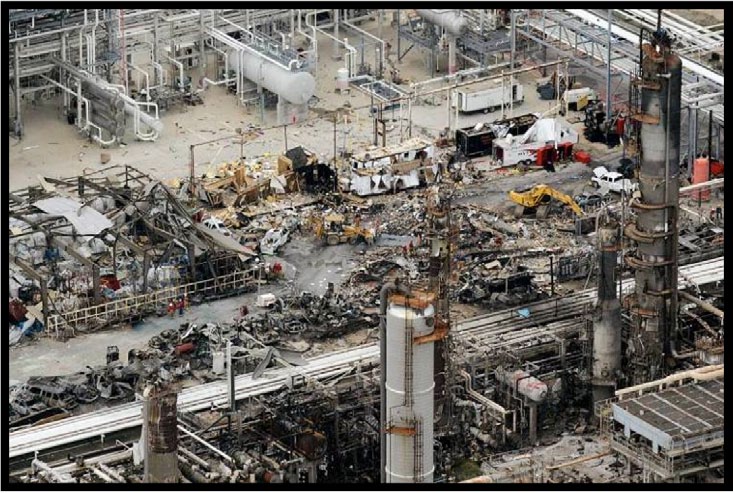

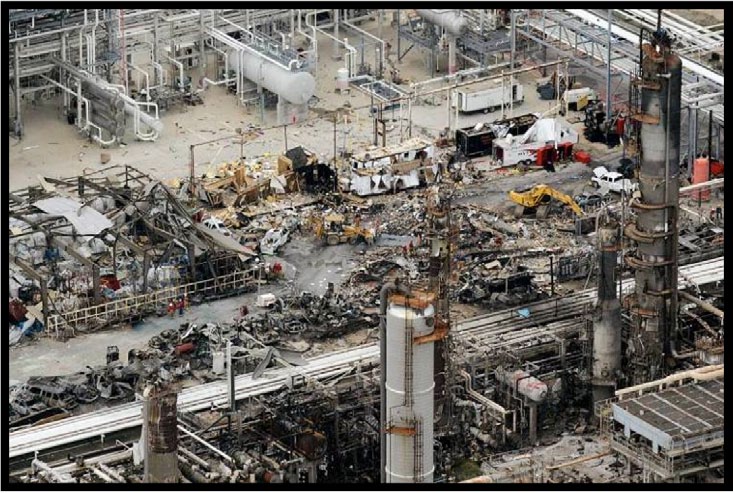

The non-sparking tools provide protection against fires and explosions in environments where there is a very high probability of sparks that form innescoille initiation flammable solvents, vapors, liquids, dusts or residues.

NOTE: It 'important to assess each situation carefully and use the tools appropriate for the risks that are present. Contact the manufacturer of tools, and the producer of flammable material (for example) for advice and information.

This category of tools do not produce or generate sparks is sometimes referred to as "cold spark". These sparks cold have a low level of heat and are not able to turn on the carbon disulfide, which have the lowest point of ignition of any other substance known to man.

Non-metals such as wood, leather, and plastic are suitable for some tools such as shovels, scoops and scrapers or are not dangerous spark friction.

The non-sparking tools provide protection against fires and explosions in environments where there is a very high probability of sparks that form innescoille initiation flammable solvents, vapors, liquids, dusts or residues.

NOTE: It 'important to assess each situation carefully and use the tools appropriate for the risks that are present. Contact the manufacturer of tools, and the producer of flammable material (for example) for advice and information.

What are the risks of both types of tools?

Both "sparks" and "non-sparking" materials can cause ignition. Two types of risks are associated with products manufactured of any material:

Ignition by friction, with an impact on them or on other materials such as steel or concrete, which generate a "normal" (mechanical or friction) spark. All instruments can ignite flammable mixtures by sparks generated by friction or shock. However, this is only true when the spark is generated arsonist: means that a spark that must have enough heat content (ie, a sufficient mass and sufficiently high temperature) and must last long enough to heat a flammable vapor-air mixture above its temperature of ignition. This is more likely in the case of sparks formed using a metal grinder that a spark generated when a hammer strikes a metal.

Primer chemically generated spark, caused by impact between some metals and some substances containing oxygen (such as rust, which is iron oxide).

Both "sparks" and "non-sparking" materials can cause ignition. Two types of risks are associated with products manufactured of any material:

Ignition by friction, with an impact on them or on other materials such as steel or concrete, which generate a "normal" (mechanical or friction) spark. All instruments can ignite flammable mixtures by sparks generated by friction or shock. However, this is only true when the spark is generated arsonist: means that a spark that must have enough heat content (ie, a sufficient mass and sufficiently high temperature) and must last long enough to heat a flammable vapor-air mixture above its temperature of ignition. This is more likely in the case of sparks formed using a metal grinder that a spark generated when a hammer strikes a metal.

Primer chemically generated spark, caused by impact between some metals and some substances containing oxygen (such as rust, which is iron oxide).

Follow the instructions below to reduce the risk of explosion and fire.

- Ensure that all non-sparking tools are kept clean and free of contaminants ferrous or otherwise, that may hinder the properties of non-sparking.

- Do not use sparking tools hand in direct contact with acetylene, which can form explosive acetylides, especially in the presence of moisture.

- Use ventilation systems in the premises as the case of removal of hazardous materials, dust and vapors from the workplace.

- Follow the usual safety procedures when sharpening of non-sparking tools with the use of eye protection and face and extracting the appropriate means to collect dust.

What is the best protection against accidental explosions?

- Follow safe work practices.

- Always evaluate a job to do in a dangerous environment (even easier)!

- Use

tools and equipment that eliminate ignition such as electric motors

that can be certified as "explosion-proof" for use in the workplace more

dangerous or non-sparking tools, with proper use and maintenance.

- Keep in mind that there are no truly non-sparking tools.

- The

flammable atmospheres include mixtures of steam-air and clouds of dust

as organic flour or coal dust. The insulation, ventilation and disposal

are methods to ensure a safe working environment.

- Use explosimeters in the workplace to protect those who work in hazardous environments.